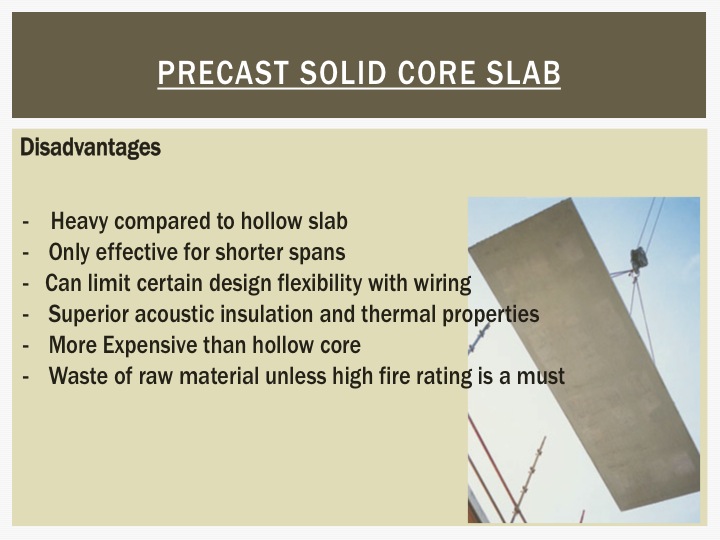

Hollow Core Precast Concrete Floor Panels Disadvantages

Precast concrete floor slab is the most fully standardized precast concrete elements.

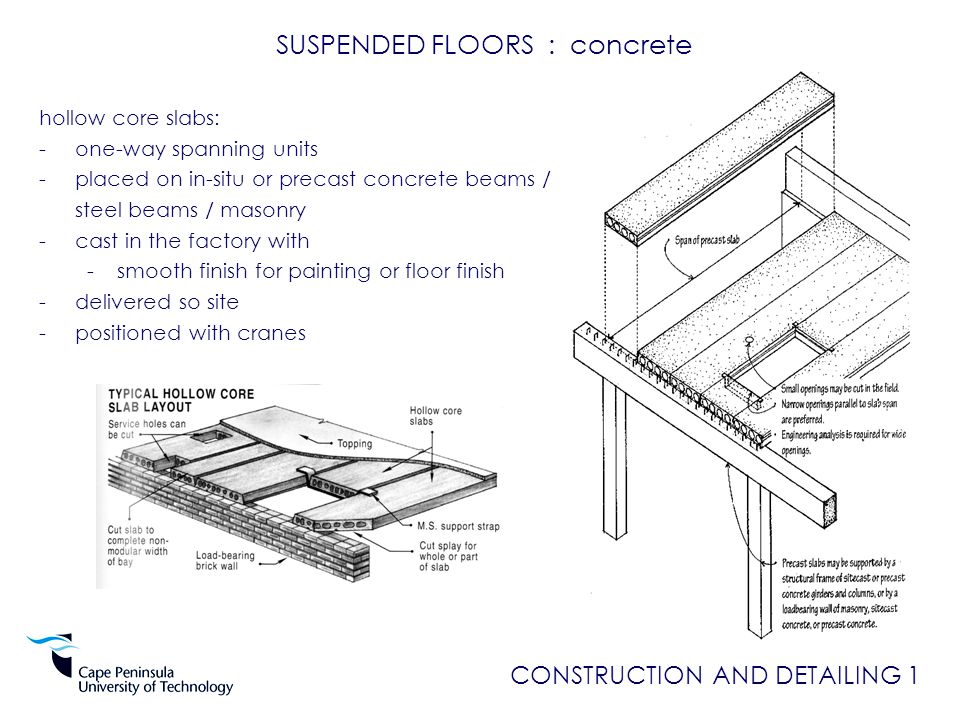

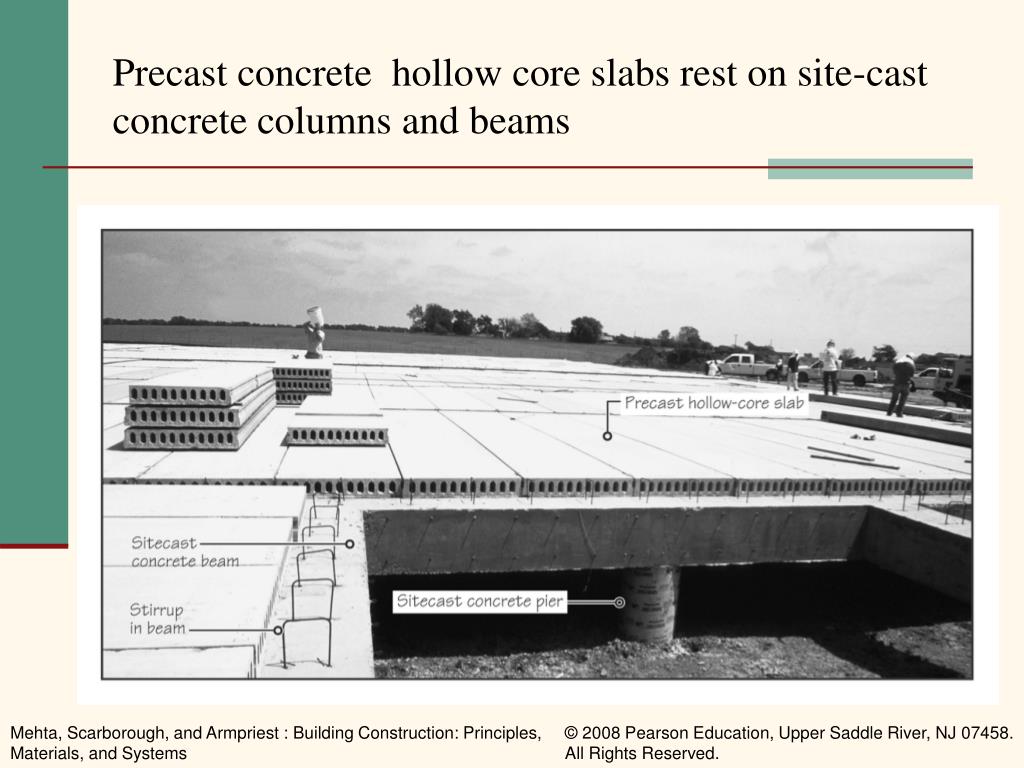

Hollow core precast concrete floor panels disadvantages. Disadvantages of precast concrete. We supplied 4x24 foot hollowcore slabs for a building floor that received a 2 inch thick concrete topping placed by the concrete contractor. They are used for making floor and roof slabs. Hollowcore planks can be attached to cmu walls steel beams or precast walls beams.

Very rapid speed of erection good quality control entire building can be precast walls floors beams etc. Part of the building was left unfinished for later use and when it was built out the owner noticed a crack that was visible on the topping surface but not on the underside of the hollowcore members which are visible from the floor below. Following are the disadvantages of precast concrete. As the heroes of flooring roofing bridges and mezzanine systems there are 7 main advantages of precast hollowcore slabs.

In addition the panels have continuous voids in them that reduce weight and cost and also may be utilized for electrical or mechanical runs. Precast floors and in particular hollowcore floors offer many advantages over alternative flooring construction methods such as in situ metal deck and timber. If not properly handled the precast units may be damaged during transport. Advantages and disadvantages of precast concrete construction advantages.

For installing a precast concrete plant heavy and sophisticated machines are necessary which requires a high initial investment a large scale of precast construction projects must be available to ensure sufficient profit. Recently a half pc slab or composite slab was developed to replace existing construction methods and to improve the performance of a pc slab system a half pc slab system hpcss is defined as a slab system that is pre stressed. There are some disadvantages to precast concrete they are discussed below. Prestressed hollowcore floors provide the most economical flooring solution for the widest variety of situations in masonry steel and concrete structures.

When precast structures are to be installed it is evident that the amount of scaffolding and formwork is considerably reduced. Rapid construction on site high quality because of the controlled conditions in the factory prestressing is easily done which can reduce the size and number of the structural members. This helps keep the construction process on track and adds another layer of efficiency to the project. Large span length with tubular hollowed out voids spanning the slabs full length these concrete slabs present a dramatic decrease in weight without sacrificing strength and durability.

Hollowcore systems are prestressed concrete plank that serve as both a ready made sub floor for a garage and a ceiling for additional living areas. Precast concrete pc slab systems have been proposed by various researchers because of their advantages in terms of quality convenience and construction period.